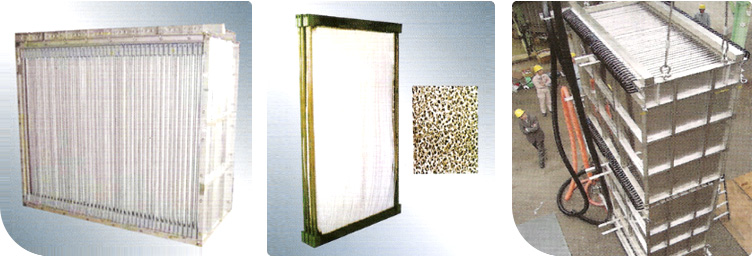

MBR Process

The MBR (Membrane Bio Reactor) process can be employed in activated sludge processes, using the membranes as liquid-solid separation instead of the usual settling. Our MBR process consists of equalization tank, effluent tank, anoxic tank, and MBR with FNR equipment in one reaction tank. Because of this structure it doesn't require sludge transfer pump.

Process Schematic Diagram

MBR Process

| Process | Description | Remark |

|---|---|---|

| Anoxic |

It returns nitrified wastewater from aerobic tank to de-nitrify, and in this process phosphorus is removed. Agitator transfers sludge to aerobic tank. |

- |

| Aerobic | On the top of aerobic tank, phosphorus is removed by aerobic organic which stimulates nitrification and absorbance of phosphorus. By implanting membrane it is able to function as sedimentation tank, filtration and disinfection tank. Treated water could be drained. Active Sludge and nitrified wastewater in aerobic tank would return to anoxic tank by gravity. | - |

| FNR | By connecting DC electric current to the iron plate it is able to extract iron ion, and supply it to aerobic tank. | - |

Benefits

- Much higher quality for treated water. (free from suspended solids)

- Retain activated sludge at high concentrations, allowing BOD as well as nitrogen to be removed efficiently.

- Stable high water permeability with minimal clogging and higher permeated water quality.

- Smaller footprint (no need of anoxic tank)

- Eliminate the sedimentation or sludge concentration process.

- More effective biological treatment allows activated sludge tank size to be reduced.

- Fewer chemical cleaning requirements.

- Energy efficient

| Qualification | Patent No. 0764642 | Maximum Contaminant Level Parameter | BOD(mg/ℓ) | ≤5 |

|---|---|---|---|---|

| SS(mg/ℓ) | ≤5 | |||

| T-N(mg/ℓ) | ≤20 | |||

| T-P(mg/ℓ) | ≤2 |